Laboratory Controlled Goods Management System

At present, the management of various laboratory standards, reagents, hazardous chemicals and other materials is mostly based on traditional manual management and manual accounting. Due to the wide variety of materials, a wide range of users, and backward storage hardware, there are many problems such as serious lag in accounting, inconvenience in finding materials, serious waste of expired materials, chaotic management mode, and even certain safety hazards.

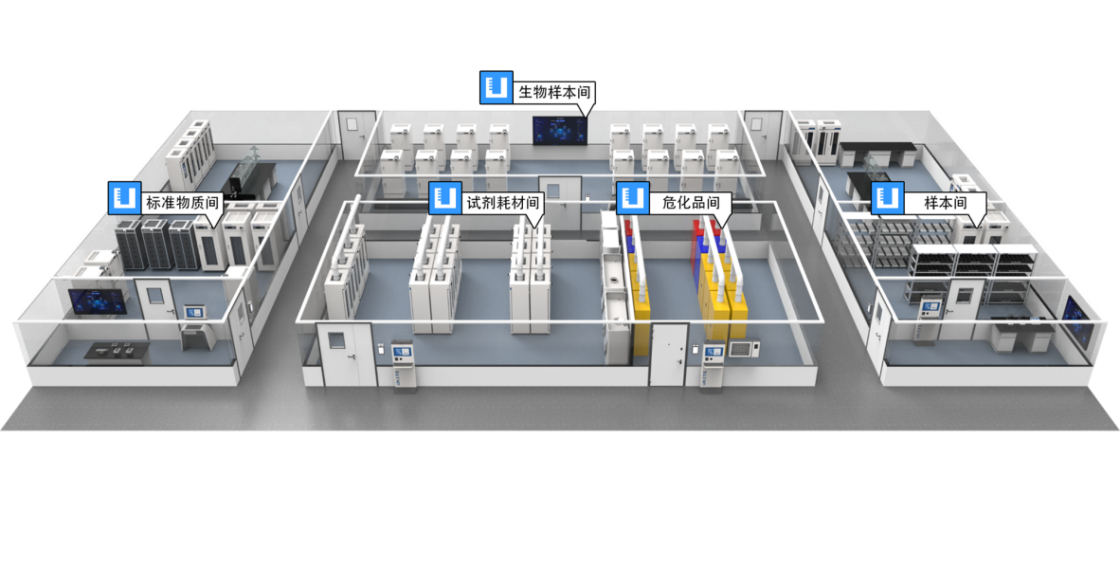

Based on this situation, Unat's matrix intelligent IoT management system came into being, which is different from other laboratory material management products. With the concept of blockchain and the design concept of Industry 4.0, it aims to establish a set of overall human-machine management system based on the concept of blockchain for all laboratories. Through the system software plus the IoT mode of intelligent storage hardware, a complete management system is designed for laboratory standards, reagents, hazardous chemicals and other materials. At the same time, each isolated system is integrated through digital information, and data is encrypted and transmitted to achieve the purpose of complete information, unchangeable, personnel sharing, and data traceability. Thereby reducing management costs, controlling safety risks, improving the internal management capabilities of the laboratory, and truly achieving the decentralized management goal of traceable sources and traceable destinations.

By incorporating all experimental materials into the same system for management, it can be seen that all kinds of materials will eventually converge into a data chain pointing to laboratory work. The ultimate goal of this system is to record the usage information of standard products, reagents, hazardous chemicals, target experimental information, experimental methods, etc., in order to improve work efficiency.

The matrix IoT management system has clear functions such as warehousing, collection, return, approval, purchase, statistics, etc. Each process has accurate data records and is transmitted to the data center in real time to achieve the digital management of all laboratory hazardous chemicals and reduce the management manpower and time costs.

Contact Us

Telephone:0512-63169078 18015479868

Fax: 0512-63165028

E-mail: jshd@jshuadi.com

18015479868@163.com

Address: Room 502, Building 2, 3000 Tongjin Avenue, Jiangling Street, Wujiang District, Suzhou City