Laboratory HVAC System

The HVAC system is the core of the laboratory. Ensuring the temperature, humidity, cleanliness, and pressure gradient of the laboratory is the top priority of laboratory construction! The laboratory HVAC system includes the following:

1. Laboratory central air conditioning system

Generally, multi-split central air conditioners are used in conjunction with fresh air air conditioning units to better control the temperature while reducing energy consumption.

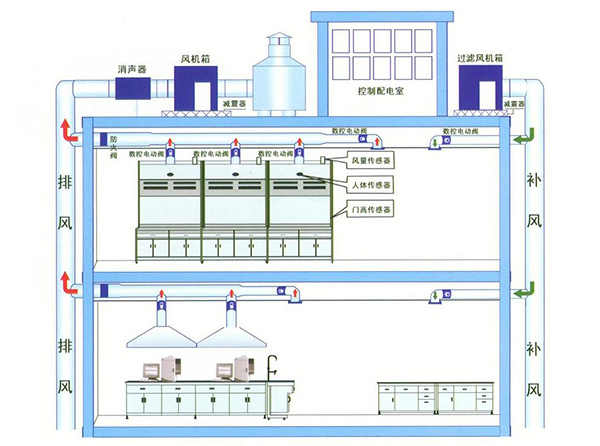

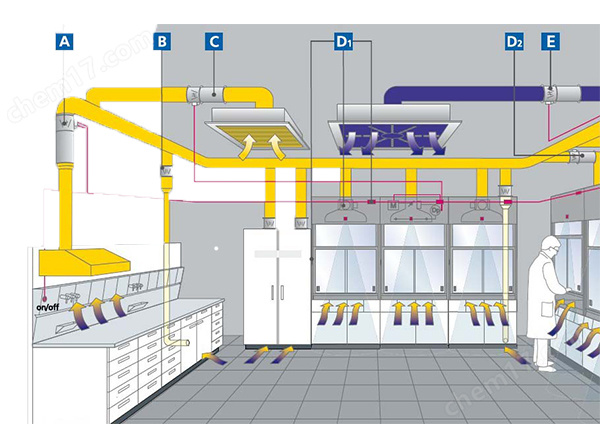

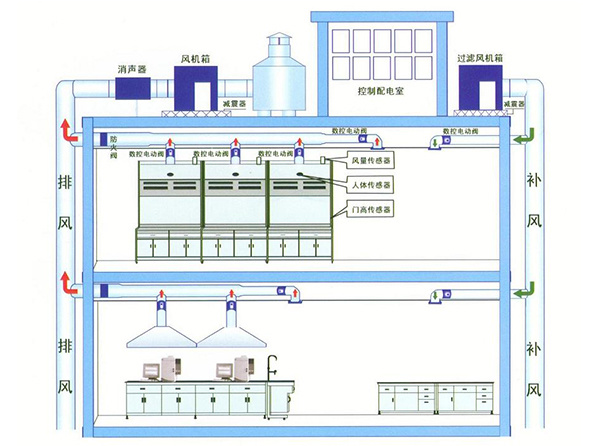

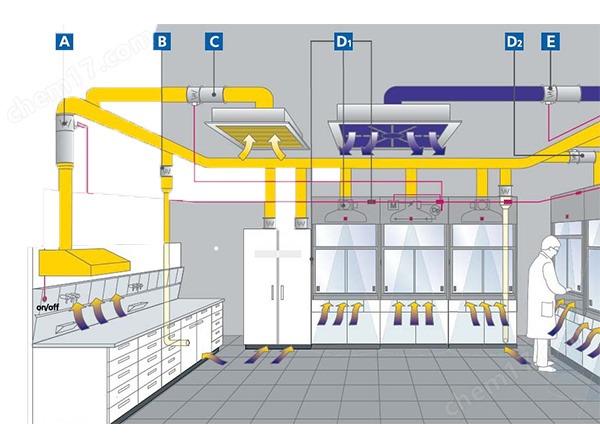

2. Laboratory ventilation system (exhaust + supply)

(1) The laboratory exhaust system generally includes the exhaust of physical and chemical laboratories, biological laboratories and physical laboratories. It consists of exhaust equipment (fume hoods, universal exhaust hoods, atomic absorption hoods, exhaust vents, etc.), exhaust ducts (flame-retardant PP exhaust ducts, fiberglass exhaust ducts, galvanized steel exhaust ducts, stainless steel exhaust ducts, etc., the specific selection depends on the use scenario and whether it is corrosive), exhaust fans (axial flow exhaust fans, diagonal flow exhaust fans, centrifugal exhaust fans and fan boxes with filters, etc., the materials include fiberglass, PP, etc., the specific selection depends on the experimental scenario and whether it is corrosive), exhaust gas treatment devices (activated carbon treatment boxes, SDG treatment boxes, acid-base neutralization towers, etc.), the main purpose of which is to exhaust toxic and harmful gases, dust, etc. in various laboratories.

(2) The laboratory fresh air supply system consists of fresh air units, galvanized air ducts, air outlets and other equipment and facilities. Its purpose is to supplement the air pressure loss caused by exhaust in the laboratory, adjust the temperature and humidity, and ensure the normal use of the laboratory and the comfort of personnel.

(3) Laboratory exhaust and laboratory fresh air supply work together under the action of the airflow organization control system and are dynamically balanced according to the use requirements. Usually, the slight negative pressure of physical and chemical laboratories, the negative pressure of biosafety laboratories, and the positive pressure of clean rooms are the results of the joint cooperation of supply and exhaust.

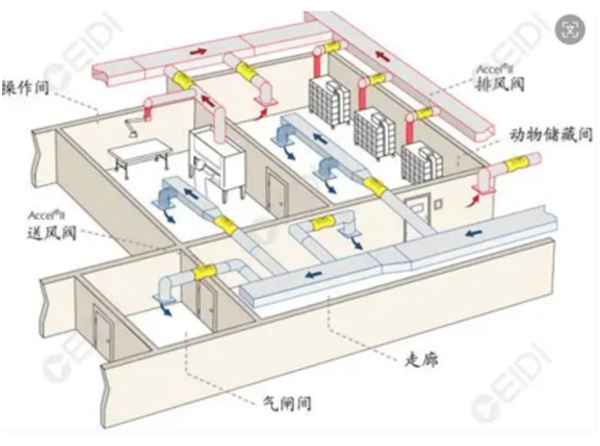

3. Clean and sterile laboratories, biosafety laboratories, animal room laboratories, and operating room HVAC systems

HVAC design is carried out according to specific usage specifications and requirements. The cleanliness levels include Class 100, Class 1,000, Class 10,000, and ordinary environment. The pressure gradients include positive pressure, negative pressure, and normal pressure.

4. Laboratory constant temperature and humidity system

As the name suggests, a constant temperature and humidity laboratory uses special equipment and facilities and professional technical means to make the indoor temperature and humidity environment meet the corresponding standard requirements and obtain more accurate experimental results.

5. Laboratory cooling and heating system

It consists of an outdoor unit, a water tank, a water pump, and water system pipes, and is used for laboratory cooling and heating regulation.

6. Laboratory waste gas treatment system

Generally, activated carbon + SDG treatment box, acid mist spray tower and other treatment equipment are used for tail gas treatment in organic and inorganic chemical laboratories. For exhaust in biosafety laboratories, filters are usually installed in the exhaust fan box for treatment.